The video shows how to properly cut thick porcelain tiles (ceramic tiles with 20 mm thickness) currently used for outdoor installation.

The cutting of these porcelain thick panels is very different from cutting standard thickness tiles. The extreme hardness of the material combined with its thickness are the main factors that will put titling tools to the test.

Main problems of thick porcelain tiles cutting

Based on many professional tilers’ experience, what often happens is that the basic blades make good cuts on very thick tiles once or twice, and then lose their cutting power. The diamond blade is so ruined after that, it can’t even be revived with the common abrasive stones.

Many tilers and brick layers have found a first solution for this, using turbo segmented blades to cut these tiles, these are more aggressive blades that easily cut this type of ceramics although with a very poor cutting finish. There is then the need to spend time after each cut to finish the tile, especially if it is going to be laid in a showing position.

Montolit advices for a perfect cut of porcelain tiles

What we recommend is to use a ceramic blade and revive it very often. If you use a low quality blade, it might need to be revived even 2 or 3 times during the same cut, with extra costs related to the use of many diamond abrasive stones.

Montolit has developed a special tile saw called DNA (SCX), used in the video above, capable of easily cutting vitrified thick tiles as well as common porcelain tiles. Even this blade should be revived, but we’re talking about doing it every 2 or 3 cuts. Additional advantages of using a DNA (SCX) blade are related to the fact that it would give a much higher cutting speed as well as a longer life span if used on thick porcelain tile.

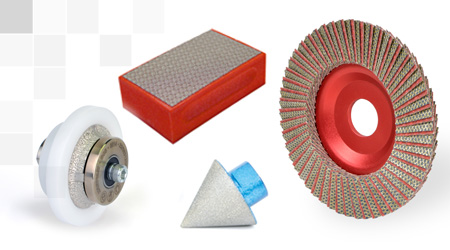

Discover more about Montolit porcelain slab cutting tools

Article created by Develed Digital Marketing