How does the dressing stone work?

It happens that even with nearly new diamond blades or diamond core bits the cutting efficiency can appear to diminish after only a few cuts because of the following reasons:

1. The diamond tool may be of low quality manufacture or defective

2. The diamond tool needs to be dressed because the diamond crown may be clogged

3. The diamond tip may be broken

Regarding item 2 –

Principally, impairment of cutting efficiency and clogging can be caused when the diamond tool is used on many different materials, especially with universal or multipurpose diamond tools that are made for tile fixers.

Under a microscope the diamond chips look like mountains tops with valleys in between them. Naturally during the cutting operation grinding dust is created and with water this dust is turned into a paste which clings to the diamond crown and fills every space and crevice or ‘valley’, hence the cause of the clogging which will bury the diamond tips and make the whole surface smooth. Also, any heat generated during cutting will harden the ‘clogging paste’ too.

Now you understand why the blade or core bit won’t cut! It only rubs, bounces or burns the surface!!

If you use a specifically made diamond tool, such as for Marble, on another material, this is another cause of loss of cutting efficiency.

However all is not lost and in either case the diamond tool can easily be ‘brought to life’ by renovation using the Montolit dressing stone.

This dressing stone is abrasive and will recover and lift the diamond tips of tool returning it to ‘like new’ cutting capabilities. The clogged hard dust is cleaned out of the ‘valleys’ allowing the blade to breathe and cut again!!

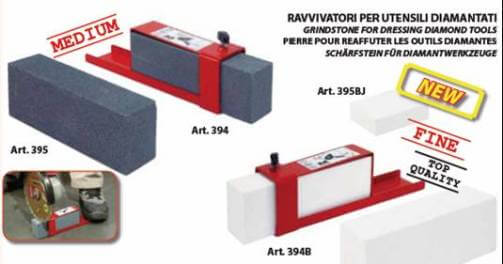

Montolit have two types of Dressing Stones:

1. A Grey dressing stone which is composed of medium sized grains adapted for dressing dry use diamond tools for cutting stones, granite and building materials.

2. A White dressing stone which is composed of fine sized grains adapted for dressing wet use diamond tools for cutting marble and ceramic.

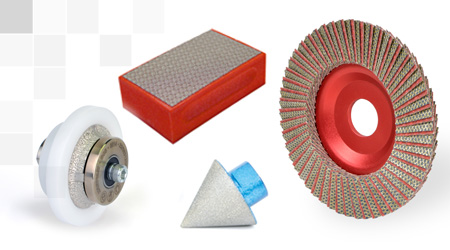

These Dressing Stones can be used with all sintered diamond tiling cutting tools.

ATTENTION!! DO NOT USE THESE DRESSING STONES TO REVIVE ELECTROPLATED DIAMOND TOOLS. THE ABRASIVE STONE WILL STRIP THE DIAMOND OFF THE CROWN

The Montolit Dressing Stones are manufactured in the following way:

The Dressing Stone are composed of a mix of Aluminium Oxide or Carborundum and an special ceramic bonding agent.

Exact measured quantities of each component is put into the mix which is molded to shape and then furnace heat treated at approximately 1280 degrees for 4 days!!

Humidity control is critical with this type of Dressing Stone. Keep it dry!!

IN CONCLUSION!!

Montolit Dressing Stones can easily help you renovate a used diamond blade or core bit.

So think about it before you condemn the Diamond Tool

It may have good life left in it, TRY DRESSING THE CROWN BEFORE GIVING IT UP!!!!