Sempre più spesso sia il posatore/piastrellista professionista che il semplice appassionato del fai da te si trovano nella necessità di effettuare fori di piccole dimensioni (diametro 5; 6; 8; 10; 12 mm) su rivestimenti in ceramica o pietra (pareti o pavimentazioni).

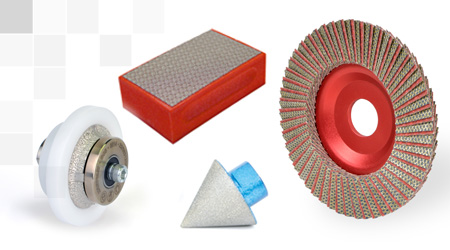

La tradizionale foratura ad acqua con frese classiche è difficoltosa in quanto richiede all’utilizzatore l’adozione di molti accorgimenti dedicati come l’acquisto di accessori per il corretto afflusso e la successiva raccolta dell’acqua necessaria al raffreddamento dell’utensile diamantato. Inoltre la foratura ad acqua necessità di specifici elettroutensili con adeguati sistemi/protezioni di sicurezza. Per risolvere questo problema sono stati recentemente messi a punto una serie di frese a secco applicabili su elettroutensili classici (trapano standard elettrico o a batteria). Questi utensili (foretti) a corona diamantata continua sinterizzata*, se correttamente utilizzati (vedi video), sono in grado di realizzare numerosi fori con un ottimo livello di precisione ed una buona velocità di foratura su qualsiasi tipo di ceramica o Gres Porcellanato.

Una domanda classica del piastrellista riguarda la quantità di fori che è possibile realizzare con queste frese a secco. La risposta corretta varia ovviamente a seconda della tipologia di materiale da forare (Ceramica,Gres Porcellanato, Granito, Marmo etc) e dallo spessore del pezzo. Ad ogni modo possiamo affermare con certezza e per esperienza diretta che, ad esempio, il foretto a secco Montolit FTJ (correttamente utilizzato…!) su una piastrella di Gres Porcellanato dello spessore di 7 o 8 mm è in grado di realizzare oltre i quaranta fori.

For dry drilling of these new materials, there have also been on the market for some time now so-called “vacuum electroplated” diamond drills such as the FS Mondrillo by Brevetti Montolit series, which have among their prerogatives extreme universatility but also poor performance (limited number of holes) since for technical reasons they are not revivable unlike the drills presented above (MONTOLIT FTJ Series) .

The need for high-speed use of these drills (minimum 10,000 rpm) then limits their application to the angle grinder only and thus their use to professionals in the field. The fields of application of these diamond cutters are numerous, we can mention the main ones:

- Fixing Sanitaryware

- Fixing Furniture

- Fixing Window Frames

- Fixing Air Conditioners or Radiators

- Making holes for cable and pipe routing

Dry diamond drill bits are now a small revolution for tilers ,electricians, plumbers and installers and are fast replacing the classic and inappropriate Tungsten Carbide (Widia®) drill bits, which are no longer suitable for the new and very hard materials such as the latest generation of Porcelain Stoneware.