LARGE FORMAT

DISCOVER ALL THE PRODUCTS

Don't waste time and improve your work, with professional equipment and electric and manual machines for cutting and drilling stone materials.

REQUEST THE CATALOGUE

Strumenti professionali per la lavorazione (movimentazione, taglio e foratura) di lastre di gres porcellanato di grandi dimensioni.

Per piastrelle di grande formato intendiamo piastrelle di dimensioni che variano dai 120 cm agli oltre 3 metri e 60 centimetri.

Questa tipologia di piastrelle giganti ha visto la sua apparizione sui mercati internazionali a partire dal 2008 e da quell momento i volumi di produzione sono aumentati senza sosta.

Alcune nazioni in particolare hanno adottato queste piastrelle molto velocemente ed oggi rappresentano già percentuali molto importanti del mercato interno.

La lavorazione di queste lastre di gres porcellanato si basa sugli stessi principi tecnici delle piastrelle di piccole e medie dimensioni ma sono necessari utensili e tecniche specifiche.

Gli utensili per la lavorazione di lastre di grande formato sono suddivisibili in 5 categorie principali a seconda della fase di lavorazione:

Movimentazione di lastre di grande formato:

La movimentazione di queste lastre è una delle fasi più delicate del processo di posa. Le lastre vengono normalmente trasportate in casse di legno orizzontali oppure su A-frame (di legno o di metallo).

Una volta che i prodotti arrivano sul luogo di posa, è necessario un muletto particolare per estrarre la cassa dal camion e posizionarla nell’area di lavoro.

Queste lastre hanno spessori che vanno dai 3 ai 20 mm e, come anticipato, si sviluppano su lunghezze ad oggi fino a 3 metri e 60 centimetri.

Per tale motivo, le piastrelle di grande formato possono flettere, torcersi e sono particolarmente fragili soprattutto in prossimità degli spigoli.

Per evitare rotture o danneggiamenti durante la movimentazione dall’area di stoccaggio all’area di lavoro, Brevetti Montolit ha creato una serie di prodotti ed accessori specifici:

– Paraspigoli con diverse altezze per la protezione degli angoli

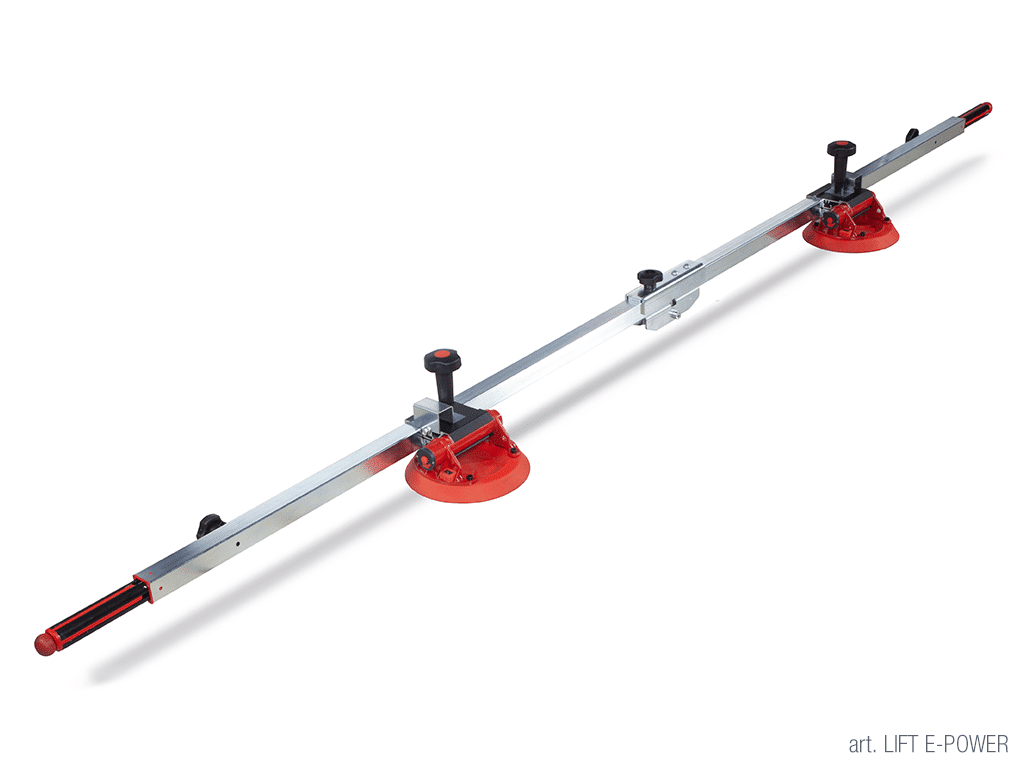

– Sistemi di movimentazione manuali regolabili, muniti di ventose professionali, con vuotometro di sicurezza in grado di mantenere la tenuta anche in situazioni estreme

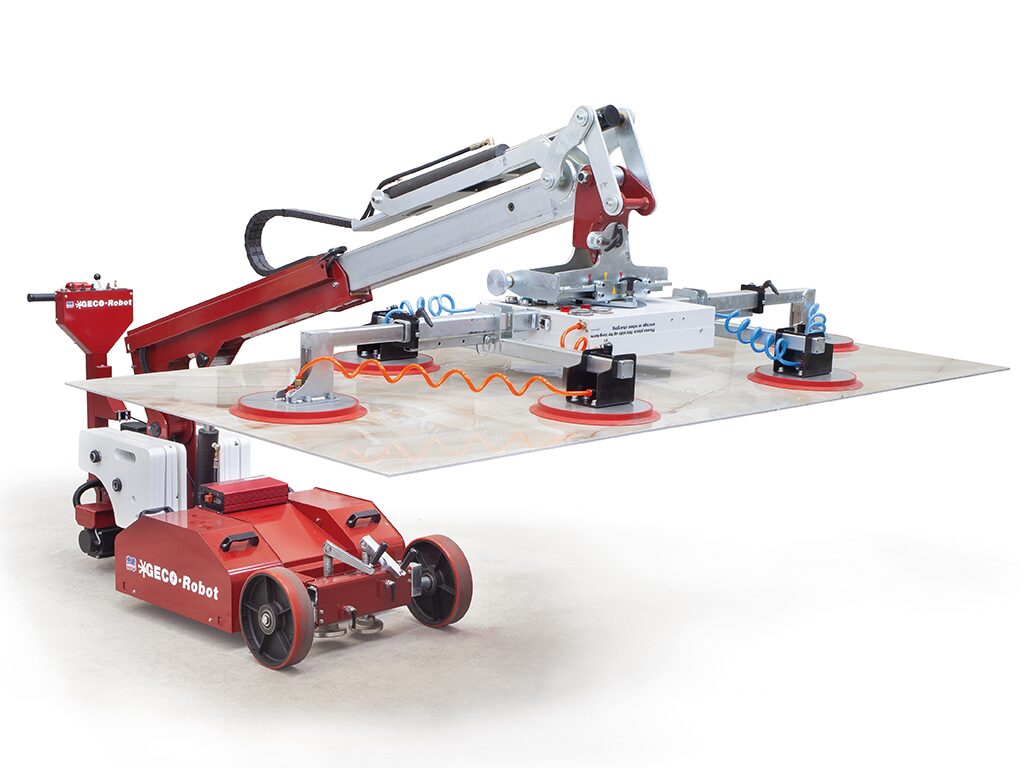

– Sistemi di movimentazione meccanici su ruote strutturati in grado di movimentare lastre con pesi molto elevati fino a 260 KG

– Carrelli/Trolley per la movimentazione di lastre all’interno dell’area di lavoro

Taglio di lastre di grande formato:

Il taglio di piastrelle giganti si basa sulla stessa tecnologia di incisione e spacco che comunemente si utilizza per le piastrelle di dimensioni standard.

Il taglio si può quindi effettuare con un sistema manuale oppure con una taglierina elettrica ed un disco diamantato.

Nel caso specifico dei grandi formati, i macchinari sono studiati per consentire al posatore di effettuare i tagli con velocità e massima precisione.

È importante sottolineare che per effetturare un taglio preciso ed evitare rotture non volute, è fondamentale che la lastra di ceramica o porcellanato sia posizionata su di un piano estremamente rigido, dritto e stabile.

I prodotti necessari per il taglio di piastrelle giganti sono i seguenti:

-Tavolo da lavoro modulare, robusto e facilmente trasportabile

-Tagliapiastrelle manuale componibile, con sistema brevettato senza ventose Flash Line

-Moto Flash Line, versione motorizzata della tagliapiastrelle manuale Flash Line

-Dischi diamantati specifici per piastrelle sottili e delicate di grande formato

Foratura di lastre di grande formato:

La foratura di piastrelle in gres porcellanato di grande formato, soprattutto sottili, è un’altra fase molto delicata della lavorazione. Sempre più spesso queste lastre necessitano di essere forate in diversi punti con fori tondi e/o squadrati.

Spesso questi fori si trovano a distanza ravvicinata nel caso di rubinetterie, box doccia o piani di cottura.

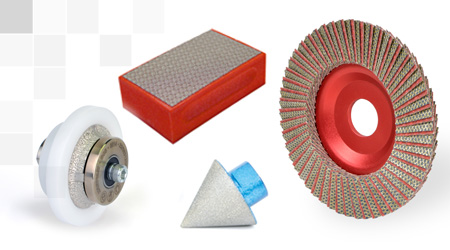

Per evitare qualsiasi tipo di inconveniente durante la fase di foratura, Montolit ha sviluppato una serie di frese diamantate specifiche per lastre giganti e sottili.

Queste frese hanno spessori ridotti e grazie a granulometrie di diamante specifiche e ad una forma particolarmente studiata, riducono le vibrazioni al minimo.

Le principali linee di prodotti per la foratura di lastre di grande formato sono:

-Dischi a secco specifici per la realizzazione di fori su lastre giganti

-Frese diamantate per fori di medio-grandi dimensioni in piastrelle di grande formato da utilizzarsi su smerigliatrice angolare

-Punte diamantate per la realizzazione di fori di piccole dimensioni su lastre di grande formato da utilizzarsi su smerigliatrice angolare o trapano

Rifinitura di lastre di grade formato:

Sempre più spesso viene richiesto da designer ed architetti di creare accoppiamenti specifici tra lastre di grande formato. Per tale ragione è necessario che i lati della piastrella subiscano lavorazioni specifiche come la bisellatura o il taglio a 45 gradi.

Effettuare queste lavorazioni a mano tramite l’uso di una semplice smerigliatrice angolare è un processo lungo con risultati non costanti a causa della lunghezza della lastra.

Montolit ha sviluppato uno strumento specifico che consente di realizzare smussi a 45 gradi o raccordi molto accurati su lastre di grande formato.

Il prodotto si chiama Toprofile ed è a tutti gli effetti un profilatore professionale portatile per piastrelle di qualsiasi dimensione.

Posa di lastre di grande formato:

Quando la lastra è lavorata e pronta per l’installazione, è possible utilizzare per la posa lo stesso sistema di movimentazione utilizzato per il trasporto della lastra dal pallet al tavolo di lavoro, il sistema di movimentazione di lastre di grande formato Superlift.

Una volta che la lastra è in posizione sulla parete o sul pavimento, è necessario che l’adesivo per piastrelle utilizzato si distribuisca uniformemente sotto la piastrella e sulla relativa superficie di contatto. Per facilitare la distribuzione uniforme del collante, Montolit ha sviluppato una ventosa battente per piastrelle e lastre.

Questa ventosa, denominata Battile, funziona con delle micro vibrazioni regolabili che facilitano la distribuzione dell’adesivo sotto la superficie della piastrella, evitando pericolosissime bolle d’aria.