The photograph shows a typical case of a breakage that occurred when the tile was laid.

Come si può vedere la “crepa” parte dall’incrocio dei due tagli realizzati presumibilmente con un disco diamantato al fine di creare l’incasso per il muro.

Queste crepe normalmente si formano quando le piastrelle sono indebolite a seguito di tagli , parziali o multipli, soprattutto laddove si vengono a formare degli angoli o spigoli.

Tecnicamente questi punti ,interrompendo la continuità del materiale, divengono i punti più fragili e delicati della piastrella.

Purtroppo le rotture non nascono durante il taglio o immediatamente dopo , bensì quando la piastrella è già posata e viene sottoposta a carichi diversi quali ad esempio il calpestio delle persone, urti accidentali, pesi di mobili e attrezzature o a sollecitazioni dovute al naturale movimento di assestamento della casa.

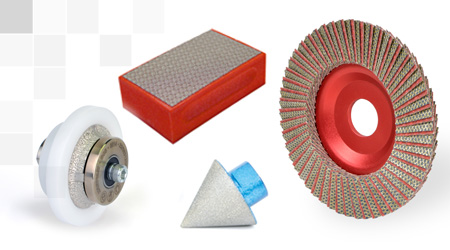

Esiste un semplice ma ingegnoso accorgimento tecnico da adottare nella fase di taglio per evitare questo genere di problema.

Si individua la posizione del vertice dell’angolo ed in corrispondenza si effettua un foro con una fresa diamantatadi piccolo diametro ( 6 / 8 mm) e solo successivamente si effettuano i due tagli con un disco diamantatospecifico, facendo attenzione a lasciare intatto il raggio creato dalla fresa.

It is precisely this radius that gives greater strength to the tile, reducing the risk of cracking when the tile is laid by up to 90 percent.