There are three main ways to make holes in tiles*

To make a square cut out – suitable for a switch box etc. – using a grinder equipped with a diamond blade

• Advantages: you use only the grinder with a compatible tile cutting blade -this is quite fast operation

• Disadvantages: During grinding a soft tile may break quite easily (like our example in the video). Grinding may cause the structure of the tile to diminish allowing the tile to fail after fixing because hairline or invisible cracks were created during the grinding process. This can frequently happen where a tile will crack from a corner due to movement caused by building settlement.

To create some kind of irregular shaped pattern on the tile edge or a circular using the grinder and then a light hammer to tap out the centre etc. to complete the job.

• Advantages: you use only the grinder with a compatible tile cutting blade

• Disadvantages: creating irregular shapes and breaking out a circle – can be a slow process – also it is very easy to break the tile during the grinding operation

To use the latest diamond drills (dry or wet use) in order to make a perfect hole

• Advantages: the hole has a good finish – the drilling operation is fast and easy – the structure of the tile is not diminished in any way making it very resistant to failure in the course of time.

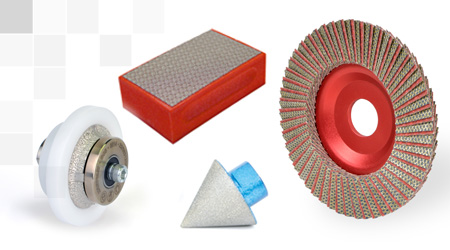

• Disadvantages: you need the correct drill bit

In the video clip below, you can see an example of these three ways to make holes in tiles. Normally, holes in the tiles are required to connect sanitary wear, electric cables, special parts etc. In the fist part of the video we made holes in a soft glazed standard tile which broke easily. Drilling very hard and compact tiles such as Enduro by Marazzi was very easy. It was possible to make the three types of hole illustrated in the video.

*We mean new type of tiles because for old and soft tiles like bi-fired tiles it is possible to make holes with manual machines (tile drills – our art. 18 and 20)