We all know that in today’s market place you can find dozens of different types of wet saws for cutting porcelain tiles, slabs of marble and granite, plus other types of stone for floor and walling.

There are many domestic and foreign brands; in fact there are wet saws of all types for professional layers and DIY’ers. It is a veritable jungle describing features and prices, and therefore, it is increasingly difficult to find the wet tile saw suitable to a professional job.

Often it can be said that it is only when we start to use the machine we soon realise we made the wrong choice. Cost’s can soon mount because then it is difficult to go back to the supplier to exchange the machine or buy another, plus the fact that you may not be able to complete the job for which you are purchased the product.

Unfortunately, in reality it isn’t easy to see immediately if the wet saw you saw in the shop will really do the job you expected it to do. However, based on our experience, we would like to suggest to you at least 5 things that can help you make the correct selection.

If you are a professional Tiler and you are looking for a wet saw (with bridge), before making a choice, consider these 5 critical points:

1. Strength and stability: it isn’t enough to just look at the wet saw. Feel the machine, move it, and check the build quality and structure. Check if there is vibration when the motor is running. Does the motor head glide smoothly along the bridge rail. Ask yourself if the build components of the machine are a close fit, if so the build quality should be good. If everything is loose then it is most likely that precision of the cut will be compromised. Look at the strength of the materials used in the build. Pressed tin sheet is not as strong as real steel plate and angle iron. Any aluminium used should be hefty casting! If the tile saw is not stable when seen in the store, it will be even less so in the yard and this will reflect in loss of accuracy for the finished cut. In addition, if the new machine is of weak build then it won’t last long and soon wear out when put to use.

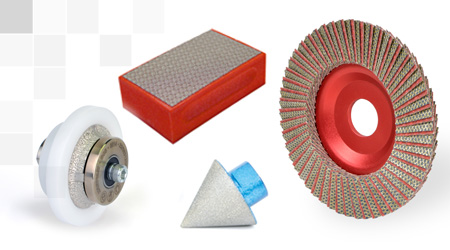

2. Diamond blade. The diamond blade is a key element of your machine!!! It is vital therefore to accurately check the type and quality of the diamond blades mounted on the wet saw. If the diamond blade is of poor quality it will compromise the cutting operations and the electric saw may be damaged. A diamond blade that doesn’t cut compels you to force the cut and this forcing can lead to a full cut “going wrong” because the blade can easily be distorted under such circumstances. If you insist in using the electric tile saw with a low quality ‘cheap’ blade the motor and drive components can also be damaged because of overheating and stress. If you buy a saw on price it can be guaranteed that it will cost you more in the long run. Why save 30 euros when you will soon have to pay perhaps 200 euro for repairs in a few months. Ask those who have already lived through this experience !!

3. Straight Cut and Jolly. Check out the process to switch from classic straight line cut, 45 ° and the Jolly. It is important that the ‘change over’ process is straight forward. When you need to repeat this process many times and it is vital that these operations are simple, fast and precise. There are several solutions on the market, you have to see what are most convincing for you.

4. Geometrical Square. If you going to cut not only porcelain tiles (7-10 mm) but also the new types of 14 mm thick tiles that are now available, such as the ‘Active’ by Graniti Fiandre for example, plus marble and granite which may be a few inches thick, it is necessary to choose a wet saw with a strong and solid geometrical square that is able to give you stability and precision during the cuts.

5. Availability of spare parts. All electrical machinery have components that are naturally subject to wear. Check with the sales man that it will be easy to find spare parts and also check the ability of the Brand to quickly resolve any issues that may emerge. The question to ask is ‘are spares and back up service readily available?’ So often, at the time of purchase, we don’t take enough care or time to think about this aspect, but of which, the importance of that will become apparent later when the machine has broken down, and all at the time when we need it most!!

Before you buy – These are simple and objective considerations that you can apply at the time of your choice.

If you want to add some point or make specific comments we will be happy to provide it in post!

> CLICK HERE TO DISCOVER THE FULL RANGE OF MONTOLIT WET TILE SAW