ELECTRIC TILE CUTTERS

DISCOVER ALL THE PRODUCTS

Don’t waste time and improve your work, with professional equipment and electric and manual machines for cutting and drilling stone materials.

REQUEST THE CATALOGUE

Tagliapiastrelle elettriche

L’evoluzione incessante dei materiali utilizzati nella posa, per semplificare, da naturali ad artificiali, sempre più esteticamente accattivanti e quindi ricercati da ingegneri ed architetti, ma anche resistenti ad acqua,variazioni climatiche, temperature, calpestio ed abrasione, ha introdotto sul mercato piastrelle sempre più compatte e tenaci da lavorare.

Questa evoluzione ha portato i tecnici Montolit a confrontarsi con nuove problematiche che hanno spinto l’azienda, già nei lontani anni ottanta, tra le prime in assoluto del settore, ad entrare nel’affascinante mondo del diamante.

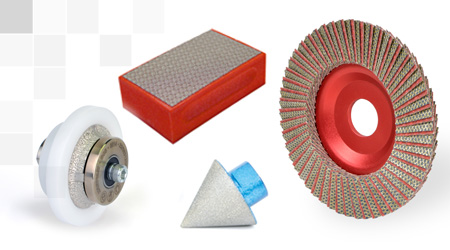

Una struttura del tutto nuova ha permesso di poter sperimentare le diverse soluzioni fino ad arrivare dai primi prototipi di utensile diamantato per il taglio e la foratura di ceramica, ad un catalogo tra i più completi sul mercato, con soluzioni praticamente per ogni tipo di lavorazione su materiale lapideo.

Dai dischi diamantati per il taglio alle macchine su cui gli stessi utensili vanno poi montati il passo è stato breve e quasi obbligato, sono così nate le prime segatrici (tagliapiastrelle) elettriche Montolit.

L’esperienza in questo settore è ormai trentennale e oggi Brevetti Montolit Spa produce e commercializza in tutto il mondo una gamma completa di tagliapiastrelle elettriche ad acqua ad uso professionale.

Queste taglierine elettriche sono ingegnerizzate con l’obiettivo di fornire al posatore una segatrice in grado di effettuare tagli precisi e rapidi, anche su piastrelle di notevoli dimensioni (lunghezze e spessori elevati).

Le caratteristiche tecniche di base che consentono alle tagliapiastrelle Montolit altissime prestazioni e di porsi sul mercato come Top di gamma sono le seguenti:

- Materie prime e componenti principali rigorosamente Made in Italy

- Struttura robusta in acciaio nichelato ed alluminio

- Motori italiani testati di comprovata affidabilità

- Sistemi di movimentazione ottimizzati per un solo operatore

- Sistemi brevettati per la regolazione ad angolo ed il bloccaggio a misura delle piastrelle anche di grande formato

- Dischi diamantati DNA top di gamma inclusi nelle taglierine elettriche

- Piani di lavoro in acciaio inox o alluminio

- Manopole e leverismi ergonomici per la movimentazione del corpo motore

- Protezioni cavi e tubi acqua per una maggior durata in cantiere

- Sistema brevettato di regolazione dei punti di appoggio anche su superifici di lavoro sconnesse

- Garanzia a vita sui difetti di fabbrica

Molti altri accorgimenti progettuali ed ergonomici fanno in modo che le taglierine elettriche Montolit siano oggi vendute ed apprezzate in oltre 100 nazioni.

Ad oggi la famiglia di taglierine elettriche ad acqua Montolit e’ composta da macchine compatte, di medie e grandi dimensioni e da macchine speciali.

Nel dettaglio ad oggi le 4 famiglie di taglierine ad acqua Montolit sono:

– Taglierina elettrica ad acqua F2 (compatta)

– Taglierina elettrica ad acqua F1 (a ponte con dimensioni variabili dai 100 ai 181 centimetri)

– Taglierina elettrica ad acqua Tornado (medie dimensioni ed elevata Potenza)

– Aquaflex (sistema universale ad acqua per l’abbattimento delle polveri)