DIAMOND DRILLING BITS

DISCOVER ALL THE PRODUCTS

Don’t waste time and improve your work, with professional equipment and electric and manual machines for cutting and drilling stone materials.

REQUEST THE CATALOGUE

Diamond Core bits

Montolit, one of the first companies worldwide to develop the dry drilling system for porcelain stoneware, has accumulated 20 years’ experience in the development, production and marketing of professional diamond tools for drilling in construction. Montolit’s range of milling cutters, drills and diamond cups now consists of several product families, each specific to a material or application.

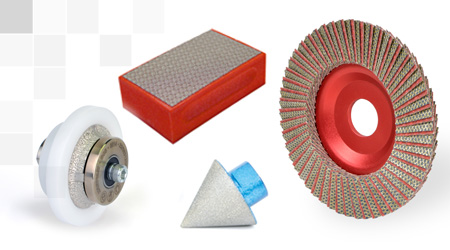

- Diamond end mills for dry drilling in porcelain stoneware, granite and marble with angle grinder Type FS

- Diamond Drills for dry drilling of thin porcelain stoneware tiles typical of large format slabs with angle grinder Type FSS

- Diamond Bits for dry drilling of thick Porcelain Stoneware and Granite (2 cm – 3/4 Inches) with angle grinder Type FT-S

- Diamond Drills for dry drilling of thick Porcelain Stoneware and Granite (2 cm – 3/4 Inches) with drill type FT

- Small diameter diamond drills for dry drilling of porcelain stoneware with drill Type FAJ (high speed) and FTJ (long life)

- Diamond drills for drilling Porcelain Stoneware, Ceramics, Marble, Granite and Natural Stone with water Type FA

- Diamond drills for water-cooled glass drilling Type FAV

- Diamond core bits for dry and wet drilling of Concrete, Reinforced Concrete, Abrasive Bricks Type FUT, FUXT, FUXLT, FX

- Diamond cutters for countersinking and reinforcing holes

- Universal diamond cutters for enlarging or shaping holes

How to choose the diamond tool needed in this case?

Here are some useful tips for choosing the ideal tool for your needs.

Assess which material is to be drilled

Obviously, this is the first aspect to be taken into consideration. Drilling very hard and thick porcelain stoneware requires very different diamond drill bits from those needed for drilling natural stone or ceramics. To simplify, we could say that the more compact and harder the material, the more high-performance diamond drills are required. Porcelain stoneware and glass, for example, are particular in this respect.

Define the type of hole finish required

Depending on whether the hole is visible or not, it is important to identify the ideal diamond cup. The aesthetic finish of the outer profile of the hole is related to both the drilling technique and the type of diamond. In general terms, we can say that water-cooled drilling provides very high hole finish and precision. It should be emphasised that in most cases the profile of the hole is then covered and therefore a high level of finishing is very rarely required.

Identify the tool you have (drill, angle grinder, core drill or special equipment)

If you already have a power tool such as a drill or angle grinder, it will be essential to choose a diamond cutter that can be properly mounted on this power tool. In general terms, a hose (which normally has rpm of around 8,000 – 11,000) will be able to drill holes much faster than a drill which normally has rpm of 800 – 1200. If the primary objective is drilling speed, the angle grinder will therefore perform better.

Planning the type of work measured as the number of holes to be drilled

In the Montolit product range there are different types of diamond cutters for drilling holes in the same type of material. The difference is often related to performance in terms of durability and speed as well as hole finish. In the case of the professional installer who needs to drill several dozens if not hundreds of holes per month, the use of professional, high-performance endurance cutters is certainly advisable. These professional milling cutters are designed to guarantee a very low cost per hole even in comparison with standard milling cutters.

Dry or wet drilling

Here again, one must assess the specific situation and the power tool at one’s disposal. The use of water to cool the tool helps to extend the life of the diamond cutter in general allows better finishes and reduces/eliminates the discomfort of dust, however, power tools with the appropriate protection and equipment are needed to work safely in wet environments.

Dry drilling guarantees convenience, speed and excellent overall performance.