We all know that dozens of different types of water tile cutters can be found on the market today for cutting porcelain tiles, marble and granite slabs, and other types of “stones” for laying. There are domestic and foreign brands, professional or DIY water tile cutters. It is a jungle of features and prices, and it is increasingly difficult to find the ideal water tile cutter (electric tile cutter/water saw as you like).

Often we only realize we did not make the right purchase at home or on the job site, when it is then “going back” is difficult and always costly (not to mention the damage from not being able to complete the job for which the product was purchased). Unfortunately, in reality, it is not easy to tell “on the fly” in the store whether the water tile cutter that the dealer is presenting to us will be suitable for our needs. In any case, based on our experience, we would suggest paying close attention to at least 5 aspects that can be of great help in making an initial selection. If you are a professional tiler and what you are looking for is a professional water (bridge) tile cutter to use assiduously, consider these 5 aspects as critical:

1. Sturdiness and stability: it is not enough to look at the water tile cutter to know whether the structure is sturdy and especially stable. The best thing to do is to move the structure and observe the level of oscillation, and “play” between the various components. If the machine is not stable when placed in the store, it will be even less so on the job site and during cutting, to the detriment of accuracy. In addition, “games” already present in the new machine will inexorably tend to increase within a few months.

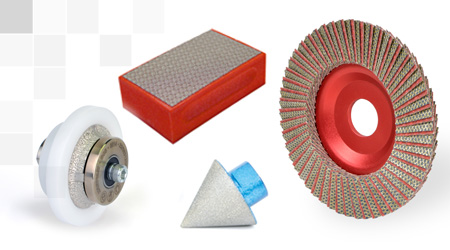

2. Diamond disc. Check the type and quality of the diamond blade included in the electric cutter. The diamond blade is an essential part of the machine. If the diamond blade is of low quality the whole operation of the cutter will be impaired and the machine itself may be damaged. A disk that does not cut forces you in the first instance to force the cut, and this forcing leads to making a “crooked” cut that you might mistakenly attribute to the water cutter. If you then insist on using the electric cutter with this low-quality disk, the motor and some transmission components will also be damaged. If the cutter costs you 30 euros less but mounts an unbranded diamond blade, it might happen that in a few months you have to spend 200 euros to repair the cutter. Ask those who have already had this experience.

3. Linear and joker cutting. Check the ease of switching between classic (linear) cutting and 45-degree cutting and Jolly cutting. Over time you will have to repeat this operation many times, and it is important that these operations can be simple, fast and accurate. There are several solutions on the market; you need to check which one is most convincing for you.

4. Team. If you think you need to cut not only 7-10 mm stoneware tiles but also work with the new types of 14mm thick porcelain stoneware tiles (Active from Graniti Fiandre for example) and with marble and granite a few centimeters thick, choose a machine with a strong, thick square that will ensure stability and cutting precision.

5. Availability of spare parts. All electrical equipment has components that are naturally subject to wear and tear. Be sure to check with your trusted dealer about the ease of obtaining such replacement parts and the company’s ability to quickly resolve any issues that may arise. At the time of purchase we often do not consider this aspect, but the importance of it emerges if we only think of the problems that a stationary water tile cutter on the construction site could cause us. These are simple objective considerations that you can make your own when making your choice. If you would like to add any points or make any special comments we will be happy to include them in the post!